Millet is an ancient grain with a rich nutritional profile and is experiencing a resurgence in popularity. Its health benefits, environmental sustainability, and versatility have made it a sought-after commodity in the food industry. As the demand for millet-based products grows, so does the need for efficient and specialized processing techniques.

Nutritional Benefits

It is a nutritional powerhouse, packed with essential nutrients. It is a good source of:

- Fiber: Millet is high in both soluble and insoluble fiber, which aids digestion, promotes gut health, and helps regulate blood sugar levels.

- Protein: Millet is a complete protein, containing all nine essential amino acids. This makes it a valuable dietary source of protein, especially for vegetarians and vegans.

- Vitamins and Minerals: It is rich in B vitamins, including thiamine, riboflavin, and niacin, which are essential for energy production and overall health. It also contains minerals like iron, magnesium, and zinc.

- Antioxidants: Millet is a good source of antioxidants, which help protect cells from damage caused by free radicals.

Environmental Benefits of Millet

It is a more sustainable grain than many others. It is drought-resistant and can be grown in a variety of climates, making it less susceptible to crop failures. Additionally, millet has a lower environmental footprint compared to other grains, as it requires less water and fertilizer.

Millet Processing Techniques

The processing of millet involves several key steps:

- Dehusking: This involves removing the outer husk from the millet grain. Dehusking machines are used to separate the edible kernel from the inedible husk.

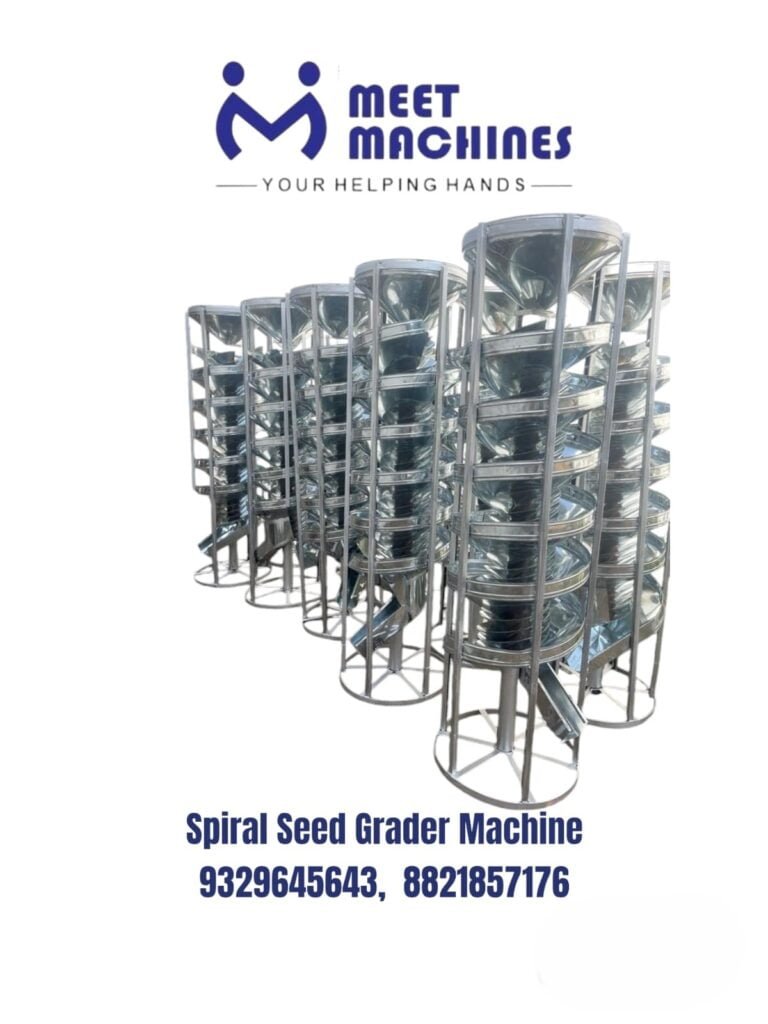

- Grading and Sorting: Millet grains are graded based on size and quality to ensure consistency in the final product. Grading machines use sieves and air separators to sort the grains into different categories.

- Polishing: Polishing removes the bran layer from the millet kernel, resulting in a smoother texture. Polishing machines use abrasive materials to gently polish the grains.

- Cleaning and Aspiration: Millet grains often contain impurities like stones and dirt. Cleaning machines use sieves and air separators to remove these impurities, while aspiration machines use air currents to separate lighter materials from heavier grains.

- Packaging: Millet grains are packaged in various sizes and types of containers for distribution and sale. Packaging machines automate the filling, sealing, and labeling of products.

Millet-Based Products

Millet can be used to create a wide variety of products, including:

- Flour: Flour can be used to make bread, pasta, cakes, and other baked goods.

- Porridge: Porridge is a healthy and nutritious breakfast option.

- Snacks: It can be used to make snacks like crackers, chips, and granola bars.

- Drinks: It can be used to make beverages like millet milk and millet beer.

The Rising Demand

The demand for millet-based products is on the rise due to their nutritional benefits, environmental sustainability, and versatility. As consumers become more aware of the health benefits of millet, they are increasingly seeking out products made from this ancient grain. This growing demand is driving innovation in the millet processing industry, leading to the development of new and improved processing techniques.

Beyond the Basics: Exploring Processing Innovations

In addition to the traditional processing methods, there are ongoing innovations in the millet processing industry. These advancements aim to improve efficiency, reduce waste, and enhance the nutritional value of millet-based products.

- Advanced Dehusking Technologies: Newer dehusking machines incorporate optical sorters and artificial intelligence to improve the accuracy and efficiency of the process.

- Energy-Efficient Processing: Techniques such as solar drying and the use of energy-efficient machinery are being implemented to reduce the environmental impact of millet processing.

- Value-Added Products: Food processors are exploring new ways to add value to millet products, such as creating fortified flours or developing innovative millet-based ingredients for the food industry.

- Byproduct Utilization: Efforts are being made to utilize this byproduct, such as husk and bran, for animal feed, biofuel, or other applications.

As the demand for millet continues to grow, it is essential to invest in research and development to ensure that the processing industry can meet the needs of consumers while maintaining sustainability and quality. By embracing innovation and adopting advanced technologies, the millet processing industry can play a vital role in promoting the consumption of this nutritious and sustainable grain.

Conclusion

An ancient grain with a rich nutritional profile and a low environmental impact is experiencing a resurgence in popularity. As the demand for millet-based products grows, the millet processing industry is undergoing significant advancements. From improved dehusking techniques to the development of new millet-based products, innovations are driving the industry forward. By embracing these advancements and investing in research and development, the processing industry can continue to meet the growing consumer demand for sustainable and nutritious food options.