Introduction

In agriculture, the quality of seeds significantly impacts crop yield and overall productivity. Seed grading, the process of sorting seeds based on various parameters such as size, weight, and shape, ensures that only high-quality seeds are used for planting. While modern seed grading machines often rely on automated systems, manually operated spiral seed grading machines offer a cost-effective and flexible alternative. These machines utilize gravitational force and spiral design principles to achieve efficient seed separation. This comprehensive write-up explores the significance, design principles, components, advantages, challenges, and future prospects of manually operated spiral seed grading machines.

Importance of Seed Grading

- Enhanced Crop Yields: Uniform seed quality contributes to better germination rates and healthier crops, leading to higher yields.

- Consistency: Seed grading ensures uniformity in seed size, which is essential for consistent planting depth and spacing, resulting in uniform crop growth.

- Disease Management: Grading helps in removing damaged or diseased seeds, reducing the risk of crop diseases.

- Market Value: Well-graded seeds have a higher market value, benefiting farmers economically and providing a competitive edge.

- Resource Efficiency: Uniform seeds lead to more efficient use of resources such as water, fertilizers, and pesticides.

Design Principles of Manually Operated Spiral Seed Grading Machines

The design of manually operated spiral seed grading machines is based on several key principles to ensure effective seed separation using gravitational force:

- Spiral Design: The spiral channel is designed to use gravitational force to separate seeds based on size and weight. The spiral’s pitch, angle, and length are crucial for achieving efficient separation.

- Gravity Utilization: Seeds move along the spiral channel under the influence of gravity, which helps in sorting seeds without requiring complex automation.

- Adjustability: Manual adjustments allow operators to modify the spiral’s angle and speed, accommodating different types of seeds and grading requirements.

- Durability: The machine is built using robust materials to withstand manual operation and ensure longevity.

- Simplicity: The design focuses on simplicity to facilitate ease of use, maintenance, and repair.

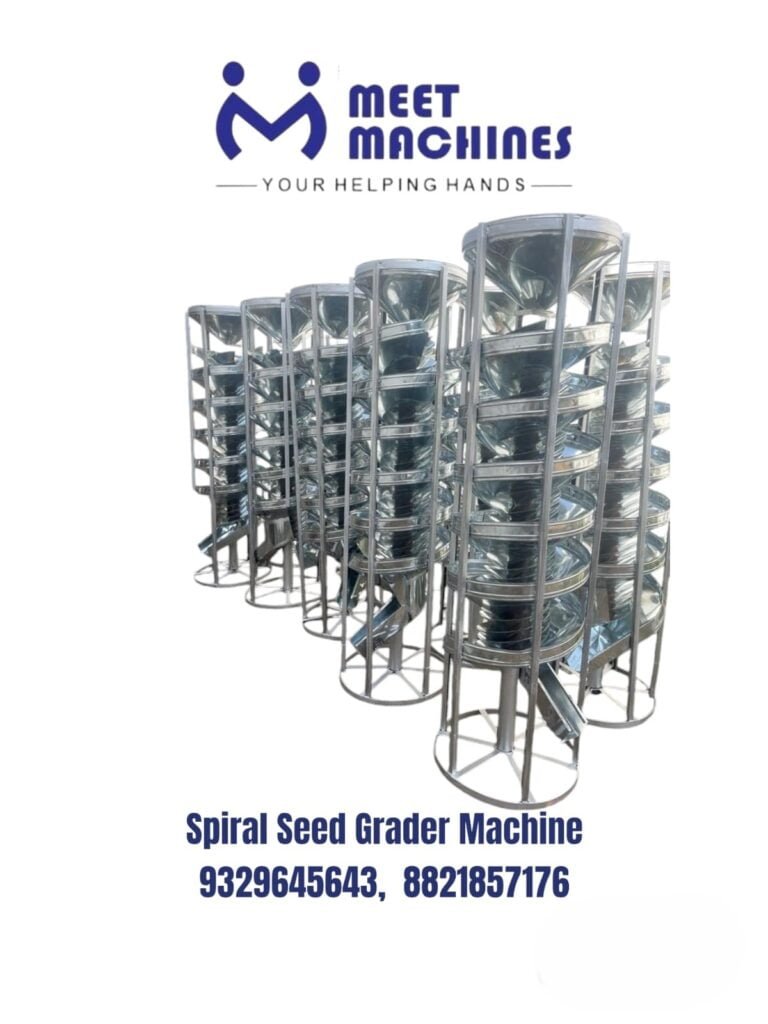

Components of Manually Operated Spiral Seed Grading Machines

A manually operated spiral seed grading machine consists of several essential components, each playing a vital role in the grading process:

- Feeding Hopper: The feeding hopper is where seeds are initially loaded into the machine. It regulates the flow of seeds into the spiral channel and ensures a consistent supply.

- Spiral Channel: The core component of the machine, the spiral channel, is where the actual grading occurs. The channel is designed with a helical spiral that facilitates the movement and separation of seeds based on size and weight.

- Adjustable Gates: Gates at various points along the spiral channel can be manually adjusted to control the flow and separation of seeds. These gates help in directing seeds to different collection bins.

- Collection Bins: Bins are placed at the end of the spiral channel to collect graded seeds based on their size and weight. Separate bins are used for different grades of seeds.

- Drive Mechanism: In manually operated machines, the drive mechanism is typically a hand crank or lever that rotates the spiral channel, enabling the separation of seeds.

- Control Panel: A simple control panel allows the operator to adjust the machine’s settings, such as the spiral angle and speed, to achieve the desired grading results.

Working Principle of Manually Operated Spiral Seed Grading Machines

The working principle of manually operated spiral seed grading machines relies on gravitational force and centrifugal action to separate seeds. Here’s a step-by-step overview:

- Feeding: Seeds are loaded into the feeding hopper, which directs them into the spiral channel.

- Movement and Separation: As the spiral channel rotates, seeds move along the channel under the influence of gravity. The spiral design creates centrifugal forces that push seeds toward the outer edges of the channel based on their size and weight.

- Grading: Larger and heavier seeds move to the outer edge of the spiral channel, while smaller and lighter seeds remain closer to the center. This separation is achieved as seeds travel along the spiral due to varying centrifugal forces.

- Collection: Adjustable gates at the end of the spiral channel direct the separated seeds into different collection bins, based on their size and weight.

Advantages of Manually Operated Spiral Seed Grading Machines

- Cost-Effectiveness: These machines are generally less expensive than automated systems, making them accessible to small-scale farmers and operations.

- Flexibility: Manual operation allows for adjustments and modifications to accommodate different types of seeds and grading requirements.

- Simplicity: The straightforward design and operation make these machines easy to use and maintain.

- Portability: Manually operated spiral graders are often portable and can be used in various locations, making them suitable for small-scale and on-site operations.

- Reduced Energy Consumption: Since the machine is manually operated, it does not require electricity, reducing energy costs and making it ideal for regions with limited power availability.

Challenges and Considerations

- Labor-Intensive: Manual operation requires physical effort and can be labor-intensive, especially when processing large quantities of seeds.

- Consistency: Achieving consistent results may be challenging without automation, as manual adjustments can lead to variability in grading.

- Speed: Manual machines typically have a lower processing speed compared to automated systems, which may affect overall productivity.

- Capacity Limitations: The capacity of manually operated spiral graders is generally limited, making them less suitable for large-scale operations.

- Maintenance: Regular maintenance is required to ensure optimal performance and manual operation may lead to increased wear and tear on components.

Technological Innovations in Manually Operated Spiral Seed Grading Machines

- Improved Materials: Advances in materials science have led to the development of more durable and wear-resistant components, extending the lifespan of manually operated machines.

- Enhanced Design: Modern designs incorporate features such as adjustable spiral channels and gates to improve the efficiency and accuracy of grading.

- Compact and Portable Models: Innovations in design have led to more compact and portable models, making them easier to transport and use in various locations.

- Ease of Maintenance: Simplified maintenance procedures and user-friendly designs make it easier to keep the machines in good working condition.

- Integration with Basic Automation: Some manually operated machines now include basic automation features, such as automatic seed feeders, to enhance efficiency while retaining manual control.

Future Prospects and Opportunities

- Sustainable Practices: Future developments will focus on sustainability, including the use of eco-friendly materials and designs that reduce environmental impact.

- Customization: Tailored designs to meet specific crop requirements and seed types will enhance the effectiveness of spiral seed grading machines.

- Government Support: Policies and initiatives that support small-scale farmers and promote the adoption of cost-effective technologies can encourage the use of manually operated seed grading machines.

- Market Expansion: Growing demand for high-quality seeds in emerging markets offers opportunities for expanding the use of manually operated spiral graders.

- Research and Development: Continued investment in R&D will drive innovations, improving the efficiency and functionality of manually operated seed grading machines.

- Integration with Basic Automation: Combining manual operation with basic automation features can enhance the efficiency of seed grading while retaining the benefits of manual control.

Conclusion

Manually operated spiral seed grading machines are an important tool for seed sorting and grading, offering a cost-effective and flexible solution for small-scale and on-site operations. By leveraging gravitational force and simple design principles, these machines provide an efficient means of achieving uniform seed quality, which is crucial for improving crop yields and market value.

Despite challenges such as labor intensity, consistency, and capacity limitations, the advantages of manually operated spiral graders, including cost-effectiveness, flexibility, and simplicity, make them a valuable asset in agriculture. Technological innovations and future developments will continue to enhance the efficiency and effectiveness of these machines, ensuring their relevance and utility in the evolving agricultural landscape. With the right support and continued advancements, manually operated spiral seed grading machines will remain a vital component of seed processing, contributing to the overall success and sustainability of agricultural practices.