Millet, a small-seeded cereal, is an important crop in many parts of the world, especially in arid and semi-arid regions. It is highly nutritious, drought-resistant, and essential to food security. However, one of the challenges in millet processing is the presence of impurities such as stones, dirt, and trash, which must be removed before further processing or consumption. Efficient cleaning, de-stoning, and grading systems are crucial to ensure high-quality millet. This write-up explores the millet de-stoning cum cleaning and grading systems with aspiration technology, which play a pivotal role in the millet processing industry.

Importance of Millet DeStoner Cum Cleaning and Grading Systems

- Quality Assurance: Removing stones, dirt, and other impurities is essential to ensure the quality and safety of the final product. Clean and graded millet is more marketable and fetches higher prices.

- Processing Efficiency: Clean millet is easier to process in subsequent stages, such as de-husking and milling. This increases overall processing efficiency and reduces wear and tear on machinery.

- Consumer Safety: Stones and other foreign materials in millet can pose a significant risk to consumers. Efficient cleaning and de-stoning systems eliminate these hazards, ensuring safe consumption.

- Economic Benefits: Improved processing efficiency and higher product quality can produce better economic returns for farmers and processors. This is especially important in regions where millet is a primary source of income.

- Compliance with Standards: Meeting quality and safety standards is essential for both local and international markets. Advanced cleaning, de-stoning, and grading systems help ensure compliance with these standards.

Design Principles of Millet DeStoner Cum Cleaning and Grading Systems

The design of millet de-stoning cum cleaning and grading systems is based on several key principles aimed at achieving efficient and thorough removal of impurities while maintaining the integrity of the millet grains. Key design elements include:

- Aspiration System: The aspiration system uses airflow to separate lighter impurities such as dust and chaff from the millet grains. This system is crucial for achieving a high level of cleanliness.

- Vibratory or Oscillating Sieves: Sieves with specific mesh sizes are used to separate millet grains from larger and smaller impurities. The vibratory or oscillating motion ensures efficient separation.

- De-Stoning Mechanism: A de-stoning mechanism, often involving a combination of air and gravity, is used to separate stones and heavier impurities from the millet grains.

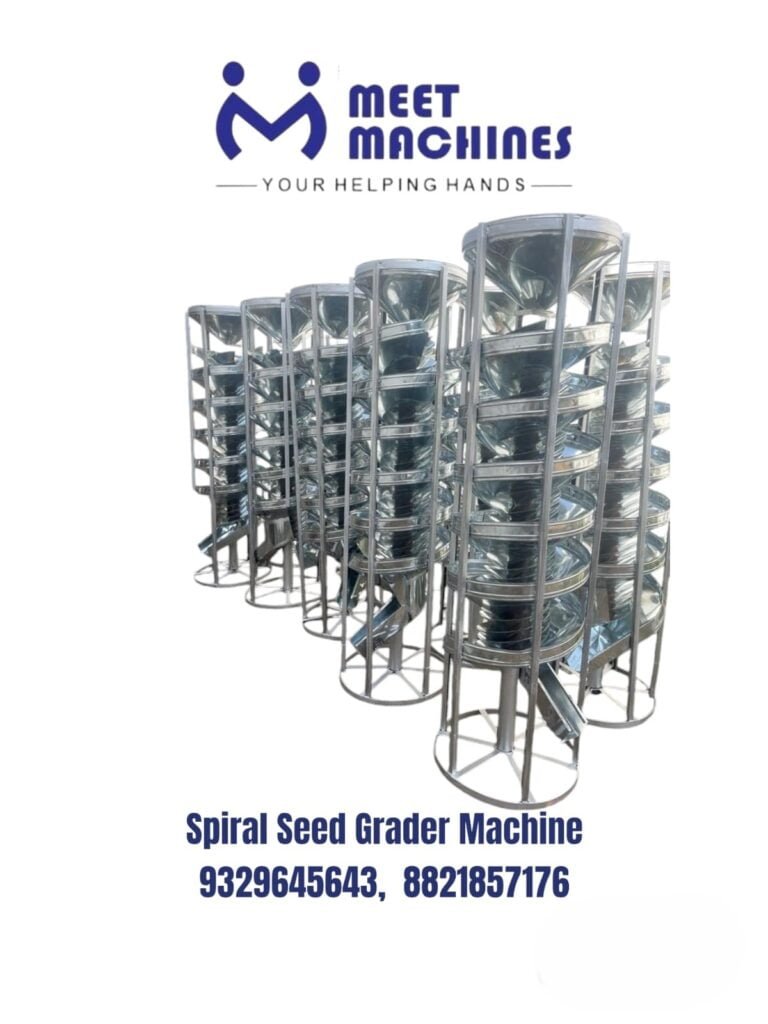

- Grading System: Grading systems separate millet grains based on size and quality. This ensures uniformity in the final product and allows for the removal of damaged or inferior grains.

- Adjustability and Customization: Different millet varieties and processing requirements may necessitate adjustable settings. Customizable components allow the system to be fine-tuned for optimal performance.

- Durability and Maintenance: Given the abrasive nature of the cleaning and de-stoning process, the machine components must be durable and resistant to wear. Easy maintenance and availability of spare parts are also critical for the longevity and reliability of the system.

Components of Millet DeStoner Cum Cleaning and Grading Systems

A comprehensive millet de-stoning cum cleaning and grading system typically consists of several key components, each serving a specific function in the overall process:

- Pre-Cleaner: The pre-cleaner removes larger impurities such as straws, sticks, and larger stones. This initial cleaning stage prepares the millet for further processing.

- Aspiration Channel: The aspiration channel uses airflow to remove lighter impurities such as dust and chaff. This component is essential for achieving a high level of cleanliness.

- Vibratory Sieve: The vibratory sieve separates the millet grains from larger and smaller impurities based on size. Different sieve sizes can be used depending on the specific requirements.

- De-Stoner: The de-stoner separates stones and other heavy impurities from the millet grains. It often uses a combination of air and gravity to achieve this separation.

- Grader: The grader sorts the millet grains based on size and quality. This component ensures uniformity in the final product and removes damaged or inferior grains.

- Aspirator: The aspirator provides additional cleaning by removing any remaining light impurities. This final cleaning stage ensures the highest level of cleanliness and quality.

Advantages of Millet DeStoner Cum Cleaning and Grading Systems

The adoption of millet de-stoning cum cleaning and grading systems with aspiration technology offers numerous advantages, including:

- Enhanced Quality: Thorough cleaning and grading ensure high-quality millet, free from impurities. This enhances the marketability and consumer appeal of the final product.

- Increased Efficiency: By automating the cleaning, de-stoning, and grading processes, these systems significantly increase processing efficiency. This leads to higher productivity and reduced labor requirements.

- Improved Safety: Removing stones and other foreign materials eliminates hazards, ensuring safe consumption of the millet. This is particularly important for meeting food safety standards.

- Economic Gains: Higher quality and efficiency translate to better economic returns for farmers and processors. The ability to produce a premium product can open up new market opportunities.

- Consistency and Uniformity: Grading systems ensure consistency and uniformity in the final product, which is important for both consumers and industrial applications.

- Reduced Machinery Wear: Clean millet reduces wear and tear on downstream processing equipment, such as de-huskers and mills. This extends the lifespan of the machinery and reduces maintenance costs.

Challenges and Considerations

While millet de-stoning cum cleaning and grading systems offer significant benefits, there are also challenges and considerations to keep in mind:

- Initial Investment: The cost of purchasing and installing these systems can be high, particularly for small-scale farmers and processors. Access to financing and subsidies can help mitigate this barrier.

- Maintenance and Repairs: Regular maintenance is essential to keep the system running efficiently. This requires technical knowledge and access to spare parts, which may not always be readily available in rural areas.

- Training and Skill Development: Operators need to be trained to use the systems effectively and safely. This can involve a learning curve and additional costs for training programs.

- Adaptability to Local Conditions: The performance of these systems can be affected by local conditions, such as the type of millet being processed, moisture content, and ambient temperature. Systems need to be adaptable to these varying conditions.

- Infrastructure Requirements: Motorized and industrial systems require reliable access to electricity and adequate space for installation and operation. This can be a challenge in remote or underdeveloped areas.

Technological Innovations in Millet DeStoner Cum Cleaning and Grading Systems

Advancements in technology continue to drive improvements in millet de-stoning cum cleaning and grading systems. Some of the notable innovations include:

- Advanced Aspiration Systems: Modern aspiration systems use sophisticated airflow dynamics to achieve more efficient separation of impurities. Adjustable airflow settings allow for customization based on specific processing requirements.

- Sensor-Based Sorting: Sensor-based sorting technology uses optical sensors to identify and remove impurities based on color, size, and shape. This technology enhances the precision and efficiency of the grading process.

- Energy Efficiency: New designs focus on reducing energy consumption without compromising performance. Energy-efficient motors and optimized mechanical components contribute to lower operational costs.

- Compact and Portable Designs: For small-scale farmers, compact and portable cleaning and de-stoning systems are being developed. These systems are easier to transport and require less space for operation.

- Integration with Other Processing Equipment: Cleaning, de-stoning, and grading systems are being integrated with other millet processing equipment, such as de-huskers and mills, to create comprehensive processing units. This integration enhances overall efficiency and productivity.

- User-Friendly Interfaces: Touchscreen interfaces and intuitive controls make it easier for operators to use and maintain the systems. User-friendly designs also improve safety and reduce the likelihood of operator errors.

Future Prospects and Opportunities

The future of millet de-stoning cum cleaning and grading systems looks promising, with several opportunities for growth and development:

- Sustainability and Eco-Friendly Designs: Future systems will likely focus on sustainability, using eco-friendly materials and designs that minimize environmental impact. Solar-powered and manually operated systems will play a crucial role in areas with limited access to electricity.

- Customization for Local Varieties: Systems tailored to specific local millet varieties will improve efficiency and output quality. Collaborative efforts between manufacturers, researchers, and local communities can drive these innovations.

- Government Support and Policies: Governments can play a significant role by providing subsidies, financial incentives, and technical support for the adoption of advanced cleaning and de-stoning systems. Policies that promote mechanization and support small-scale farmers will be crucial.

- Market Expansion: As demand for millet-based products grows, there will be increased opportunities for processors to enter new markets. High-quality cleaned and graded millet can cater to health-conscious consumers and niche markets globally.

- Research and Development: Continued investment in research and development will drive technological advancements. Partnerships between academic institutions, industry, and government agencies can accelerate innovation and address the challenges faced by millet producers.

- Digital Integration: The integration of digital technologies such as IoT (Internet of Things) and AI (Artificial Intelligence) can enhance the efficiency and effectiveness of millet cleaning and de-stoning systems. Real-time monitoring, data analysis, and predictive maintenance can optimize the entire process.

Conclusion

Millet de-stoning cum cleaning and grading systems with aspiration technology are transformative tools that can significantly enhance the efficiency, productivity, and economic viability of millet processing. By automating the cleaning, de-stoning, and grading processes, these systems not only save time and labor but also improve the quality of the final product. While there are challenges in terms of cost, maintenance, and adaptability, the benefits far outweigh these hurdles.

The future of millet cleaning and de-stoning systems lies in technological innovations, sustainability, and customized solutions that cater to local needs. With the right support from governments, research institutions, and industry, these systems can play a pivotal role in ensuring food security, improving livelihoods, and fostering economic development in regions where millet is a staple crop. As demand for nutritious and sustainable food sources grows globally, millet and its efficient processing through advanced cleaning and de-stoning systems will continue to gain importance.