Introduction to Spiral Grader Machines

Spiral grader machines are indispensable tools in the agricultural industry, specifically designed to efficiently sort and grade various types of produce. These machines employ a spiral mechanism to achieve precise grading, ensuring uniformity and quality in agricultural outputs. The fundamental purpose of a spiral grader machine is to classify produce based on size, shape, and weight, which is vital for maintaining consistency and meeting market standards.

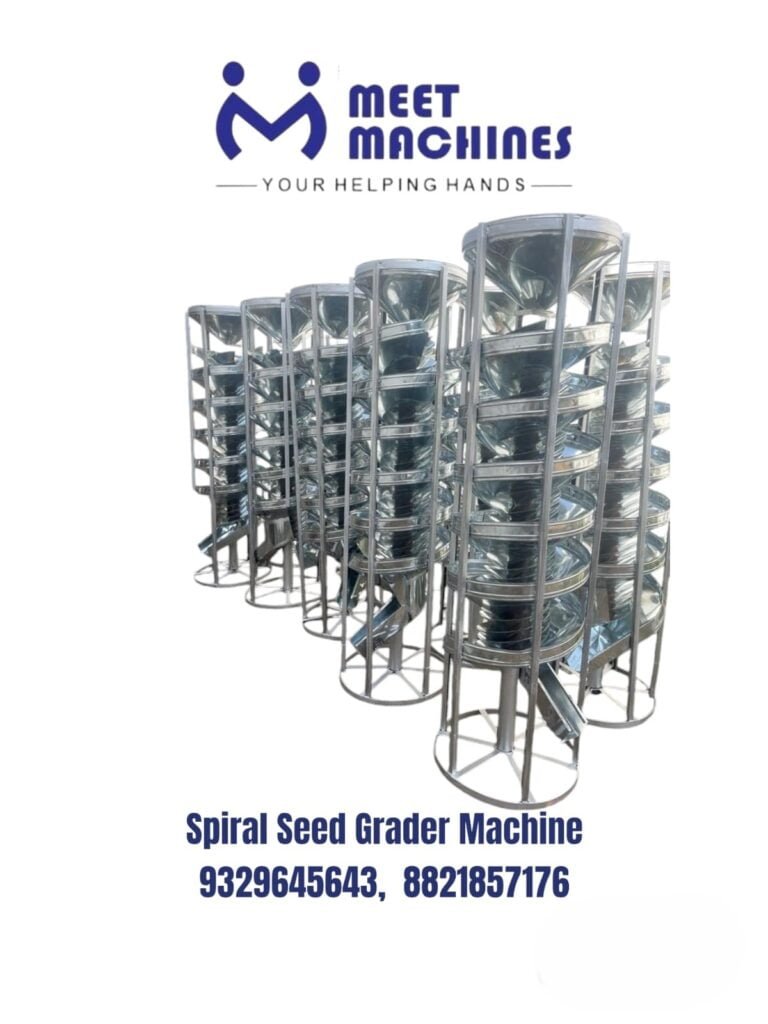

At the core of a spiral grader machine is a series of rotating spirals that facilitate the sorting process. Produce is fed into the machine, where it encounters these spirals. As the produce moves along the spirals, it is categorized into distinct grades, ensuring that each item is processed according to its specific attributes. Essential components of a spiral grader machine include the feeding hopper, sorting spirals, collection bins, and control mechanisms. Advanced models may also incorporate automated features for enhanced precision and efficiency.

Various crops can be effectively graded using spiral grader machines, including fruits, vegetables, nuts, and seeds. The accuracy of these machines is particularly crucial for delicate produce, where manual sorting could result in significant damage or inconsistency. Precision grading not only enhances the quality and appearance of the produce but also increases its market value, as consumers and retailers are assured of receiving goods that meet stringent quality criteria.

For farmers, investing in a spiral grader machine can significantly streamline the post-harvest process. While the spiral grader price might initially seem steep, the long-term benefits of reduced labor costs, improved produce quality, and higher marketability offer substantial returns on investment. Understanding the key features and operational intricacies of these machines is paramount for making an informed purchase decision, thereby optimizing agricultural productivity and profitability.

Advantages of Using Spiral Grader Machines

Spiral grader machines offer a multitude of benefits that revolutionize farming operations. One of the primary advantages is the significant increase in efficiency that these machines bring. Traditional manual grading processes are not only time-consuming but also prone to human error. A spiral grader machine, equipped with advanced technology, can sort produce quickly and accurately, significantly reducing the time required for this essential task.

Accuracy is another crucial benefit of using spiral grader machines. With precise calibration settings, these machines can sort products based on size, shape, and weight with remarkable consistency. This ensures that the sorted produce meets the desired quality standards, leading to satisfied customers and minimized waste. For farmers, this accuracy translates into improved yield quality which, in turn, can enhance market value.

Another advantage lies in the spiral grader’s capacity to handle large volumes of produce effortlessly. This is particularly beneficial during peak harvest seasons when the workload is at its highest. A spiral grading machine can manage the volume of produce that would otherwise require an extensive labor force, thereby streamlining the entire grading process.

One of the compelling financial benefits is the reduction in labor costs. By automating the grading process, farmers can cut down on the number of workers needed, which significantly lowers labor expenses. This also mitigates the risk of labor shortages, ensuring that operations continue smoothly regardless of workforce variability.

Real-world testimonials vouch for these benefits as well. For instance, John Carter, a farmer from Iowa, highlights that using a spiral grader machine drastically reduced his labor costs by 40% and increased his grading speed by 300%. Such firsthand experiences underline the practical advantages and substantial return on investment that spiral grader machines offer.

In essence, the integration of spiral grader machines into farming processes not only modernizes operations but also leads to improved productivity, higher yield quality, and significant cost savings. These advantages make spiral graders a valuable asset for any forward-thinking agricultural business.

Selecting the Right Spiral Grader Machine for Your Farm

The process of selecting the right spiral grader machine for your farm involves careful consideration of various key factors. Understanding these aspects not only ensures that you invest in a machine that optimally meets your specific needs but also maximizes the productivity and efficiency of your farming operations.

First and foremost, the type of crop you are cultivating plays a crucial role in determining the appropriate spiral grader machine. Different crops have differing sizing requirements and a machine designed for grading potatoes might not perform equally well with apples. Therefore, it is important to choose a machine specifically suited to your crop type.

Another critical factor is the volume of produce you aim to process. Machines come in varying capacities, and matching this capacity to the output of your farm will ensure smooth operation and prevent bottlenecks. For instance, a high-capacity machine would be necessary for large-scale farms to handle the significant volume of produce efficiently.

Durability and ease of maintenance are also paramount when choosing a spiral grader machine. Investing in a durable model reduces the risk of frequent breakdowns, which can lead to costly downtime. Similarly, a machine that is easy to maintain minimizes operational disruptions and prolongs the equipment’s lifespan.

Cost is a pivotal consideration but should be evaluated in conjunction with the benefits and features offered. While a lower spiral grader price may seem attractive, it is essential to weigh it against the machine’s quality, capacity, and longevity. Striking a balanced decision will essentially lead to better long-term returns on your investment.

For expert advice, farmers can consult with industry experts or peers who have experience with specific models. Evaluating user reviews and ratings can also provide valuable insights into the machine’s performance and reliability. Comparing different brands and models will provide a clearer perspective on the varied options and ensure the selection of the most suitable machine for your needs.

Ultimately, a well-informed decision on the right spiral grader machine will enhance operational efficiency, maintain product quality, and contribute significantly to the productivity of your farm, highlighting the importance of every factor and recommendation considered.

Maintenance and Best Practices for Spiral Grader Machines

Ensuring the longevity and efficiency of your spiral grader machine involves a meticulous approach to maintenance and operational best practices. Routine maintenance is imperative to prevent unexpected machine downtime and to optimize operational performance. Regularly cleaning the machine, adhering to lubrication schedules, and conducting thorough inspections are all integral components of maintaining a spiral grader machine.

Cleaning protocols should include daily removal of debris and thorough weekly washes. Debris buildup can hinder the machine’s performance and lead to more significant issues. Use non-abrasive cleaners and avoid high-pressure water applications to protect sensitive components. Lubrication schedules, as specified by the manufacturer, should be strictly followed. Typically, lubrication is necessary daily for high-use environments and weekly under normal conditions. Grease fittings and moveable parts require specific attention to ensure smooth operation.

Common troubleshooting tips involve checking for wear and tear on the grader spirals and ensuring all bolts and fittings are secure. Regular inspections should cover electric, hydraulic, and mechanical systems. Any signs of leaks, frayed wires, or abnormal sounds should be addressed immediately to prevent further damage. Often, tightening bolts, replacing worn parts, or clearing obstructions can resolve minor issues and maintain the machine’s optimal functionality.

Best practices ought to center on adherence to manufacturer guidelines. These manuals provide detailed instructions for operation and maintenance tasks. Deviating from these guidelines can void warranties and lead to suboptimal performance. Training sessions provided by the manufacturer or authorized dealers can be invaluable. Investment in ongoing education about equipment updates and advanced techniques can significantly benefit operational efficiency.

Additionally, keeping a log of maintenance activities can provide invaluable data for predicting future needs and scheduling preventative tasks. Farmers should leverage resources such as manufacturer helplines, online forums, and local experts for further technical support and training.

Learn how spiral grader machines revolutionize the agricultural industry by providing efficient, precise, and automated sorting and grading of produce. Discover the advantages, key features, maintenance best practices, and considerations for selecting the right spiral grader machine to enhance farm productivity and profitability. Explore real-world testimonials and expert advice to make an informed investment decision.